Steel Notching Machine H-150

Steel Notching Machine H-150

The Steel Notching Machine H-150 is engineered for precise coping and notching of angle steel, channel steel, and H-beam steel. It performs accurate notching, coping, and trimming, and supports R-corner and C-corner punching. Built with a high-rigidity hydraulic structure, it ensures clean cut surfaces, minimal deformation, and consistent accuracy during welding and assembly.

Ideal for steel structure fabrication, racking systems, and structural metalwork, the H-150 improves productivity and repeatability, making it an essential solution for efficient steel notching.

To learn more about the application and precision notching methods of the Steel Notching Machine, please refer to the technical article:

“Operation Safety and Notching Accuracy Control of Steel Notching Machines”

Functions:

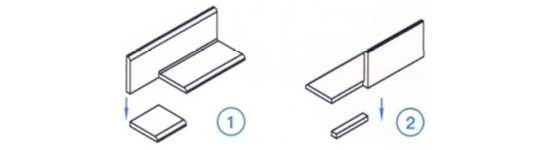

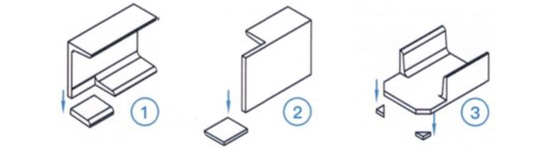

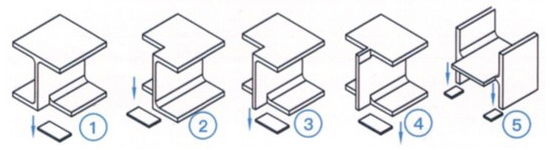

- Designed for notching and interlocking processing of angle steel, channel steel, and H-beams. The upper tooling removes the flange of section steel, while the lower tooling performs bottom notching for interlocking, capable of R-notch and C-notch operations.

Performance:

-

Provides fast and smooth shearing, reducing labor and energy consumption compared to conventional cutting methods, while lowering defect rates.

-

Optional roller lifter assists feeding of heavy and long workpieces, saving manpower and improving efficiency.

-

Consistent notching quality ensures verticality, parallelism, and flatness for subsequent welding processes, effectively reducing deformation caused by thermal expansion.

Safety:

-

For angle steel, channel steel, and H-beams, lower dies must be changed according to the workpiece. Dies are tested for durability, ensuring quick and safe replacement.

-

Operators can hold the workpieces safely without direct exposure to danger zones. Following proper operation guidelines effectively prevents accidental injuries.

|

Machine Type |

Steel Notching Machine |

|||

|

Model |

H-150 |

|||

|

Motor Power |

5HP / 4P |

|||

|

Machine Dimensions |

1000 x 800 x1500 mm |

|||

|

Machine Weight |

1300 kg |

|||

|

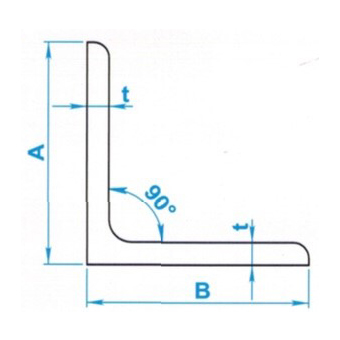

Angle Steel Notching |

||||

|

|

|

|||

|

Workpiece Section Dimensions (Unit: mm) |

||||

|

A x B |

25 x 25 |

30 x 30 |

40 x 40 |

45 x 45 |

|

t |

3 |

3 |

3 / 5 |

4 / 5 |

|

50 x 50 |

60 x 60 |

65 x 65 |

70 x 70 |

75 x 75 |

|

4 / 5 / 6 |

4 / 5 |

5 / 6 / 8 |

6 |

6 / 9 / 12 |

|

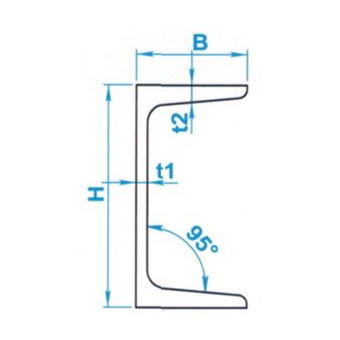

Channel Steel Notching |

|||||

|

|

|

||||

|

Workpiece Section Dimensions (Unit: mm) |

|||||

|

H x B |

75 x 40 |

100 x 50 |

125 x 65 |

150 x 75 |

150 x 75 |

|

t1 |

5 |

5 |

6 |

6.5 |

9 |

|

t2 |

7 |

7.5 |

8 |

10 |

12.5 |

|

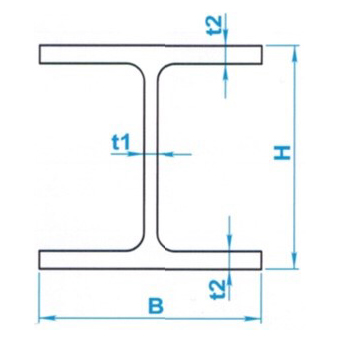

H-Beam Notching |

||||||

|

|

|

|||||

|

Workpiece Section Dimensions (Unit: mm) |

||||||

|

H x B |

100 x 50 |

100 x 100 |

125 x 60 |

125 x 125 |

150 x 75 |

150 x 100 |

|

t1 |

5 |

6 |

6 |

6.5 |

5 |

6 |

|

t2 |

7 |

8 |

8 |

9 |

7 |

9 |

<<BACK