Operation Safety and Precision Control of Steel Notching Machines

What is a Steel Notching Machine?

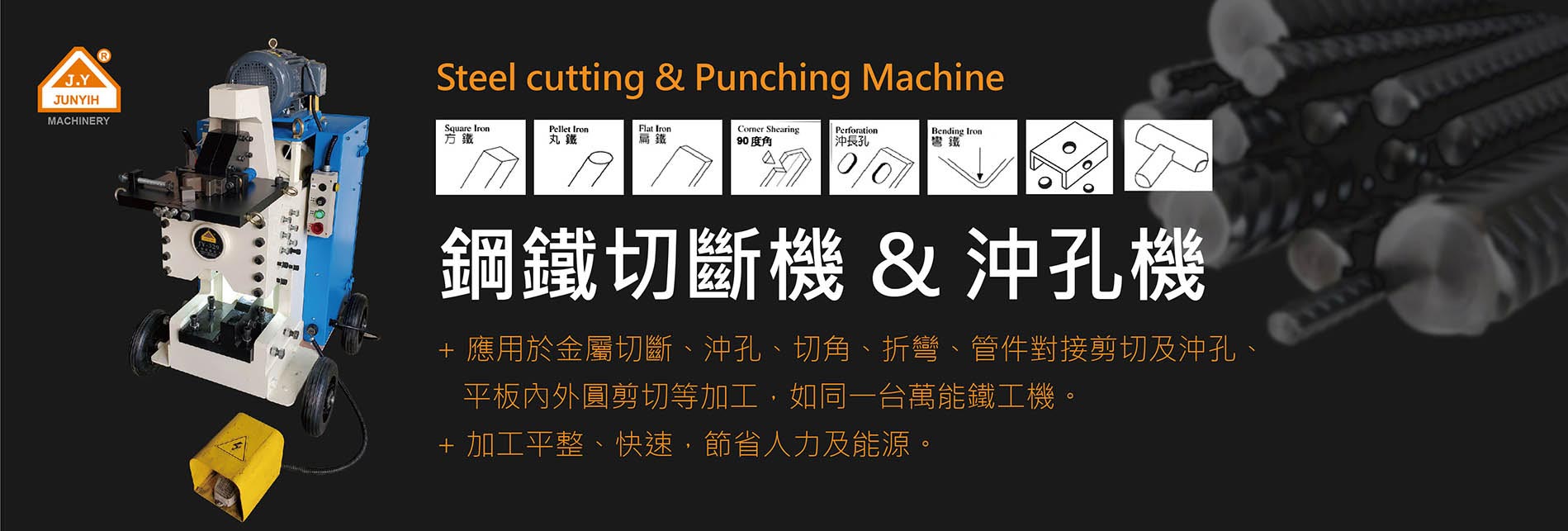

A Steel Notching Machine is designed for precise cutting and notching of section steel, angle steel, and steel plates. It enables accurate straight or angled cuts, making it widely used in construction components, metal fabrication, and signboard frames. Since the notched edges directly affect structural strength and appearance, operators must focus on both safety and accuracy control.

Safety Guidelines for Operation

1. Proper Workpiece Clamping

• Ensure the workpiece is firmly secured to prevent movement during cutting.

• Anti-slip clamps and positioning devices help improve safety.

2. Protective Devices

• Machines are usually equipped with safety guards and emergency stop buttons. Operators should confirm their functionality before use.

• Always disconnect power before changing or servicing tools to avoid accidental start-up.

3. Operator Training

• Workers should be familiar with the control panel to avoid misoperation.

• Pressure and angle settings must be adjusted when processing different thicknesses or materials.

4. Regular Maintenance

• Inspect hydraulic systems, oil quality, and seals regularly to maintain consistent pressure.

• Keep cutting blades sharp; dull tools should be re-sharpened or replaced immediately.

Methods for Precision Control

1. Proper Pressure and Stroke Settings

• Adjust hydraulic pressure according to workpiece thickness and angle, leaving a 10–20% safety margin to prevent overload.

2. Mold and Blade Accuracy

• High-quality molds and blades ensure smooth cuts with minimal burrs.

• Regular calibration reduces angle deviations caused by wear.

3. Positioning Systems

• Use precision rulers or CNC positioning systems to achieve consistent accuracy.

• Especially important in batch production to maintain uniform specifications.

4. Cutting Speed and Cooling

• Excessive speed may reduce accuracy and accelerate blade wear.

• Adequate lubrication and cooling lower friction and temperature, ensuring stable performance.

Applications of Steel Notching Machines

• Construction components: Beam and angle steel connections.

• Signboard industry: Aluminum and steel frame processing.

• Hardware and metal manufacturing: Mass production of section steel parts.

In addition, multi-functional equipment such as Ironworker Machines or Universal Ironworker Machines often integrates steel notching functions along with punching and cutting, making them popular for small and medium-sized factories.

The Steel Notching Machine plays a vital role in metal fabrication and construction steel processing. By following proper safety procedures and applying accurate pressure, mold calibration, positioning systems, and lubrication, operators can achieve consistent and precise notching results.

For businesses seeking greater efficiency and versatility, advanced solutions such as Ironworker Machines or Universal Ironworker Machines provide multi-functional performance to meet diverse production needs.

To learn more about the applications and precision cutting design of the Steel Notching Machine, please visit JUNYIH MACHINERY’s Steel Notching Machine H-150 product page to see how it achieves both high safety and exceptional cutting accuracy.