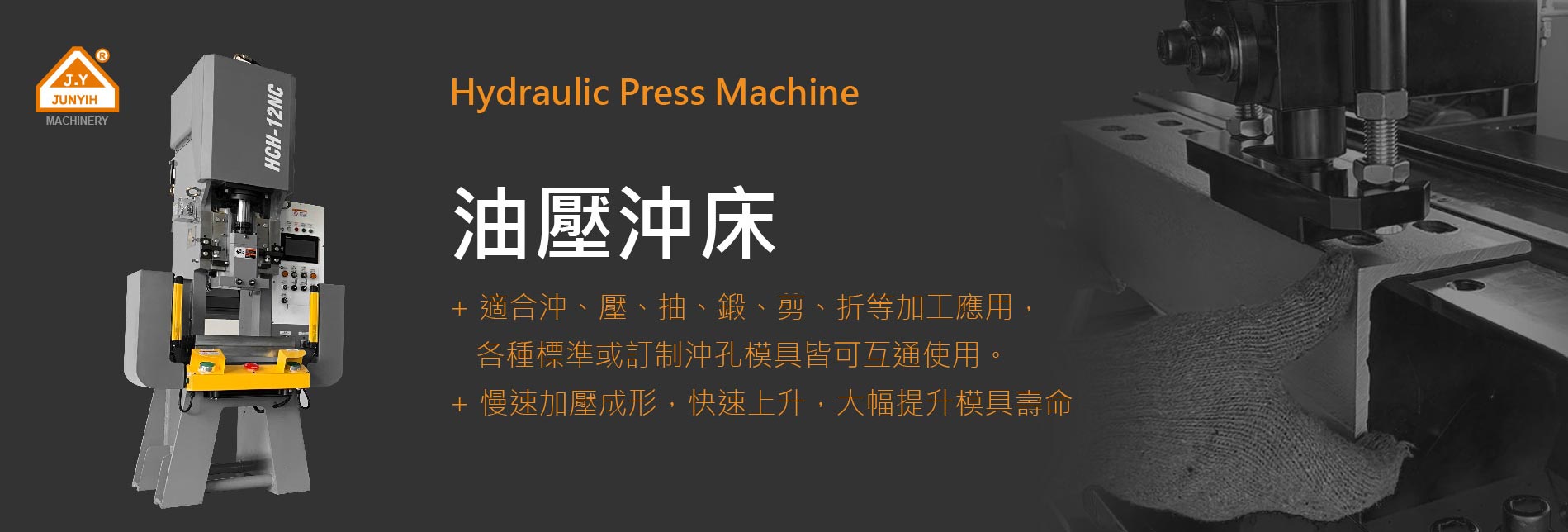

Comparison Between Hydraulic Press Machines and Mechanical Presses

In the metalworking industry, press machines are essential equipment. The two primary types commonly used are Hydraulic Press Machines and Mechanical Presses.

Although both perform similar operations such as punching, forming, cutting, and pressing, they differ significantly in power source, pressure control, operational characteristics, and application scope.

Different Power Sources

• The Hydraulic Press Machine uses hydraulic oil as its power source. Pressure is generated through the hydraulic cylinder and piston to deliver stable and continuous force.

The Mechanical Press, on the other hand, relies on a flywheel and crankshaft structure to produce instantaneous impact force.

• The hydraulic system’s advantage lies in its ability to provide consistent and sustained pressure, making it ideal for deep drawing, bending, and forging processes that require prolonged pressure.

In contrast, the mechanical press offers faster operation but only short bursts of pressure, making it more suitable for continuous punching or thin-sheet stamping.

Differences in Pressure Control and Precision

• The Hydraulic Press allows precise adjustment of pressure, stroke, and speed through hydraulic valves and a PLC control system, offering excellent performance in precision forming and die protection.

• The Mechanical Press has a fixed structure, meaning its pressure and stroke are not easily adjustable. It’s less adaptable for varying workpiece thicknesses or material types.

For products requiring high precision — such as automotive parts, electronic components, or screw forming — hydraulic presses ensure stable forming accuracy and extended die life.

Operation and Safety

• Modern hydraulic presses are equipped with PLC control, touchscreen operation panels, and safety light curtains, allowing operators to configure settings easily while ensuring workplace safety.

• In contrast, traditional mechanical presses use a more manual setup and require additional guarding systems to enhance safety.

Maintenance and Energy Consumption

• While hydraulic systems require periodic oil replacement and seal inspection, they have fewer moving parts and lower wear, resulting in stable long-term maintenance costs.

• Mechanical presses use gears and crankshafts that demand more frequent lubrication and mechanical servicing.

• In terms of energy efficiency, hydraulic presses equipped with energy-saving systems can significantly reduce noise and minimize power loss during operation.

Comparison Table

|

Category |

Hydraulic Press Machine |

Mechanical Press |

|

Power Source |

Hydraulic oil cylinder system |

Flywheel & crankshaft mechanism |

|

Processing Precision |

High – adjustable pressure |

Moderate – fixed stroke |

|

Suitable Operations |

Deep drawing, forming, forging, bending |

Thin-sheet punching, continuous production |

|

Operational Safety |

High – PLC control & safety light curtains |

Lower – requires extra protection較低,需額外防護 |

|

Maintenance Cost |

Medium to Low |

Medium to High |

|

Energy Efficiency |

Low noise, energy-saving |

Higher kinetic energy loss |

If you need high precision, stable performance, and versatile forming capability, the Hydraulic Press Machine is the better choice.For high-speed, large-volume production, the Mechanical Press remains advantageous in cost and cycle speed.

JUNYIH MACHINERY’s Hydraulic Press Machines feature a robust high-rigidity frame and PLC control system, customizable tonnage and stroke settings, and optional automatic feeding and die-protection systems—meeting diverse industrial processing requirements.

Would you like to compare the differences between the Hydraulic Press Machine and the traditional Mechanical Press in terms of pressure control, operation method, and application fields? Please refer to JUNYIH MACHINERY’s SD C-Frame Precision Hydraulic Press for detailed specifications and performance information.