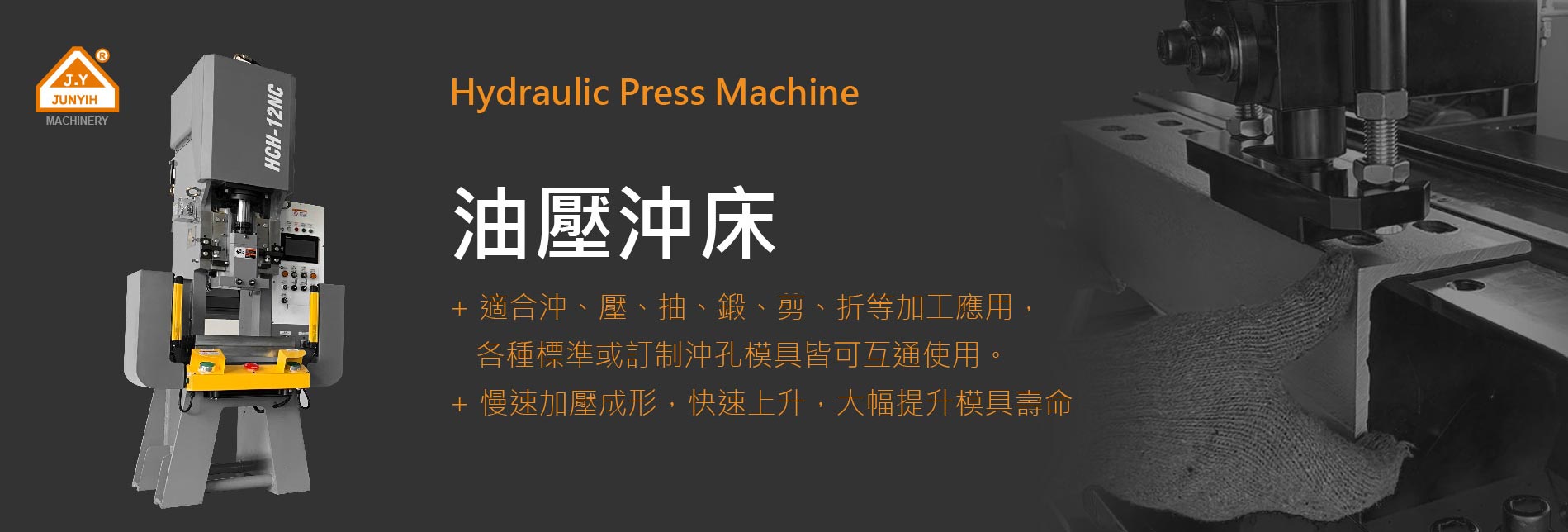

LE C-Frame Precision Hydraulic Press

LE C-Frame Precision Hydraulic Press

Model: HCH-LE

Capacity: 12–60 tons

LE C-Frame Precision Hydraulic Press features a high-rigidity welded one-piece frame, ensuring excellent stability and precise output force during metalworking processes such as punching, forming, shaping, bending, and cutting.

With its PLC control system, operators can easily set stroke, pressure, and speed, minimizing die wear and improving production accuracy.

The LE Series hydraulic press supports quick die change systems, back gauge positioning, foot switch or two-hand control, significantly increasing production efficiency.

Widely used in screw manufacturing, hardware components, electronic parts, bicycle parts, and automotive parts industries.

Precision:

- The slider is designed with a threaded fine-adjustment structure at the lower stroke limit, ensuring micro-adjustment accuracy.

- Full-floor structure with high-rigidity steel plate welding and integrated machining, ensuring stable and precise stamping performance.

- Convex guide design allows easy clearance adjustment, offering high rigidity, impact resistance, and low wear.

Performance:

- Rear-exit quick-insert type slide rod design. The upper and lower limit positions can be precisely set, suitable for heavy-load stamping and applications requiring ejector functions.

- Hydraulic power system provides energy-saving, low-noise operation without mechanical flywheel inertia loss during stroke, making it suitable for punching, pressing, drawing, forging, shearing, and bending processes.

- Die clamping system is compatible with conventional mechanical press machines, allowing interchangeability of both new and existing dies.

- Air-cooling forced cooling system supports continuous long-time operation.

Safety:

- Designed in compliance with labor safety inspection standards.

- PLC automatic control with inching, single-stroke, automatic feeding, and multi-machine linkage modes.

- Piano-style control panel allows selection of three operation modes: single-hand, double-hand, or foot pedal.

- Equipped with safety light curtain to prevent accidental injury.

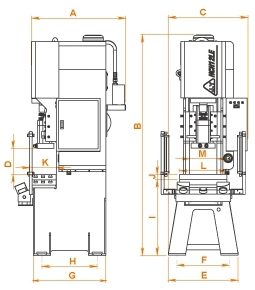

|

Exterior Size |

HCH-12LE |

HCH-18LE |

HCH-25LE |

HCH-40LE |

HCH-60LE |

| A | 900 | 1049 | 1078 | 1166 | 1354 |

| B | 2100 | 2152 | 2332 | 2520 | 2770 |

| C | 751 | 773 | 857 | 960 | 1181 |

| D | 250 | 280 | 290 | 300 | 350 |

| E | 665 | 684 | 812 | 906 | 1086 |

| F | 500 | 585 | 610 | 695 | 846 |

| G | 690 | 850 | 990 | 1090 | 1277 |

| H | 525 | 650 | 790 | 870 | 1010 |

| I | 720 | 715 | 740 | 730 | 750 |

| J | 50 | 55 | 60 | 70 | 80 |

| K | 250 | 273 | 323 | 360 | 430 |

| L | 450 | 500 | 600 | 700 | 800 |

| M | 258 | 274 | 316 | 356 | 446 |

| Unit:mm | |||||

|

Item / Model |

Unit |

HCH-12LE |

HCH-18LE |

HCH-25LE |

HCH-40LE |

HCH-60LE |

| Stamping Capacity | tons | 12 | 18 | 25 | 40 | 60 |

| Stroke | mm | 60 | 70 | 80 | 90 | 100 |

| Closing Height | mm | 190 | 210 | 210 | 210 | 250 |

| Max. Mold Height | mm | 250 | 280 | 290 | 300 | 350 |

| Slider Adjustment | mm | 110 | 120 | 120 | 130 | 130 |

| Slide Area | mm | 191x359 | 207x393 | 231x424 | 254x470 | 320x515 |

| Die Hole | mm | Ø38.1 | Ø38.1 | Ø38.1 | Ø50.8 | Ø50.8 |

| Table Size | mm | 250x450 | 270x500 | 320x600 | 360x700 | 430x800 |

| Table Aperture | mm | Ø130 | Ø150 | Ø165 | Ø180 | Ø200 |

| Table Thickness | mm | 50 | 55 | 60 | 70 | 80 |

| Main Motor | HP | 2HP / 4P | 3HP / 4P | 5HP / 4P | 7.5HP / 4P | 10HP / 4P |

■ Specifications and table dimensions can be fully customized. In addition, we welcome inquiries for die manufacturing, quick die change systems, feeding equipment, and complete automation solutions.

HCH-LE