Hydraulic Press Machine - Common Problems and Solutions

Overview of Common Hydraulic Press Machine Issues

Hydraulic Press Machines may experience problems such as insufficient pressure, abnormal speed, oil leakage, or unstable product accuracy during long-term operation if not properly operated or maintained. These issues are often related to the hydraulic system, valves, or die settings. Through proper inspection and maintenance, such problems can be effectively resolved — extending machine life and improving production efficiency.

Common Problems and Root Cause Analysis

1. Insufficient Pressure or Failure to Build Pressure

Possible Causes:

• Low oil level or poor-quality hydraulic oil.

• Worn hydraulic pump or clogged valve components.

• Oil leakage from pipelines or fittings.

Solutions:

• Check the oil tank level and refill or replace hydraulic oil if necessary.

• Clean or replace filters and inspect valve cores.

• Retighten fittings or replace damaged seals.

2. Irregular or Sticking Slide Movement

Possible Causes:

• Insufficient lubrication or worn guide rails.

• Air trapped inside the hydraulic cylinder.

Solutions:

• Apply adequate lubrication with the specified grease.

• Bleed air from the hydraulic cylinder and recalibrate the stroke.

3. Machine Vibration or Abnormal Noise

Possible Causes:

• Loose foundation bolts or unstable base.

• Air bubbles in the hydraulic pump or clogged suction filter.

Solutions:

• Ensure the machine is securely fixed to the foundation.

• Clean the filter and replace the hydraulic oil to maintain pressure stability.

4. Dimensional Inaccuracy or Rapid Die Wear

Possible Causes:

• Improper pressure setting during punching.

• Misaligned or oversized die clearance.

Solutions:

• Verify pressure settings and adjust according to material thickness.

• Recalibrate die alignment to ensure upper and lower dies are centered.

Maintenance and Servicing Recommendations

• Check oil level and quality before starting the machine daily.

• Clean machine surfaces and guide rails weekly to maintain cleanliness.

• Inspect electrical control systems and safety light curtains monthly.

• Replace hydraulic oil and filters every six months to prevent contamination.

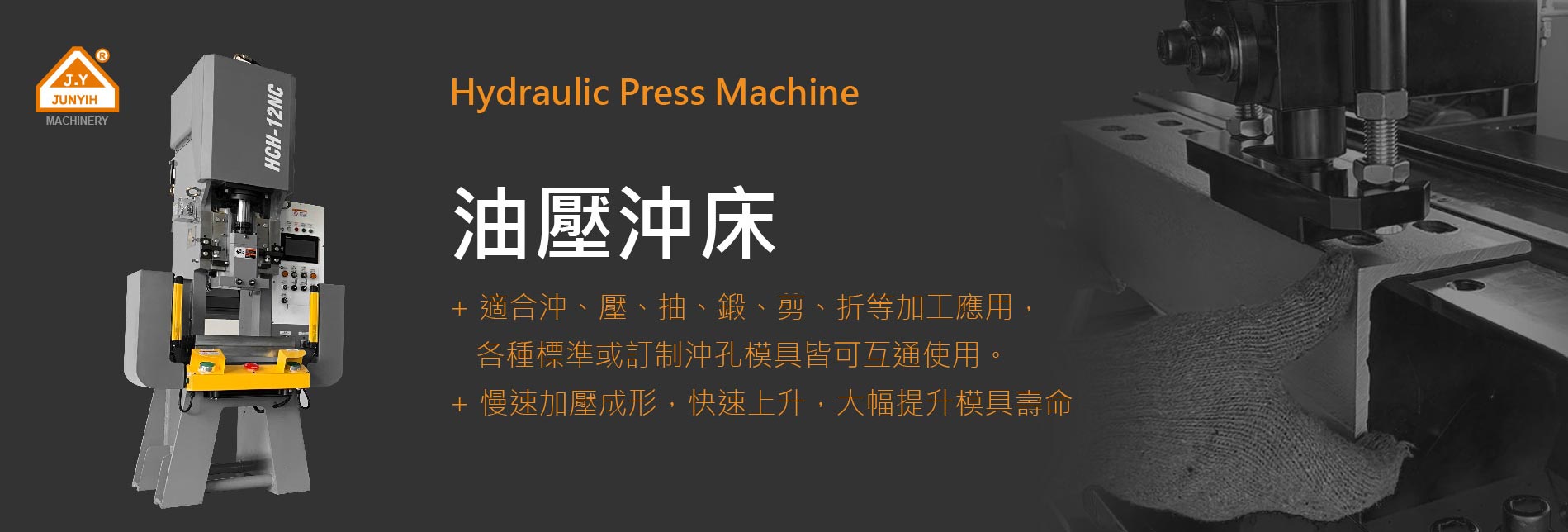

JUNYIH MACHINERY’s Hydraulic Press Machines are built with a high-rigidity frame structure, equipped with PLC control and safety protection systems, ensuring long-term stability while minimizing maintenance frequency.

With regular maintenance and proper operation, the lifespan of a Hydraulic Press Machine can be extended several times over. Consistent maintenance not only ensures product accuracy but also reduces downtime and maintenance costs. If abnormalities such as pressure loss, oil leakage, or unstable forming accuracy occur during operation, stop the machine immediately for inspection to prevent damage to critical components.

If you would like to learn more about Hydraulic Press Machine maintenance, servicing, and common troubleshooting methods, please visit JUNYIH MACHINERY’s product introduction page to explore the full range of models and application cases.