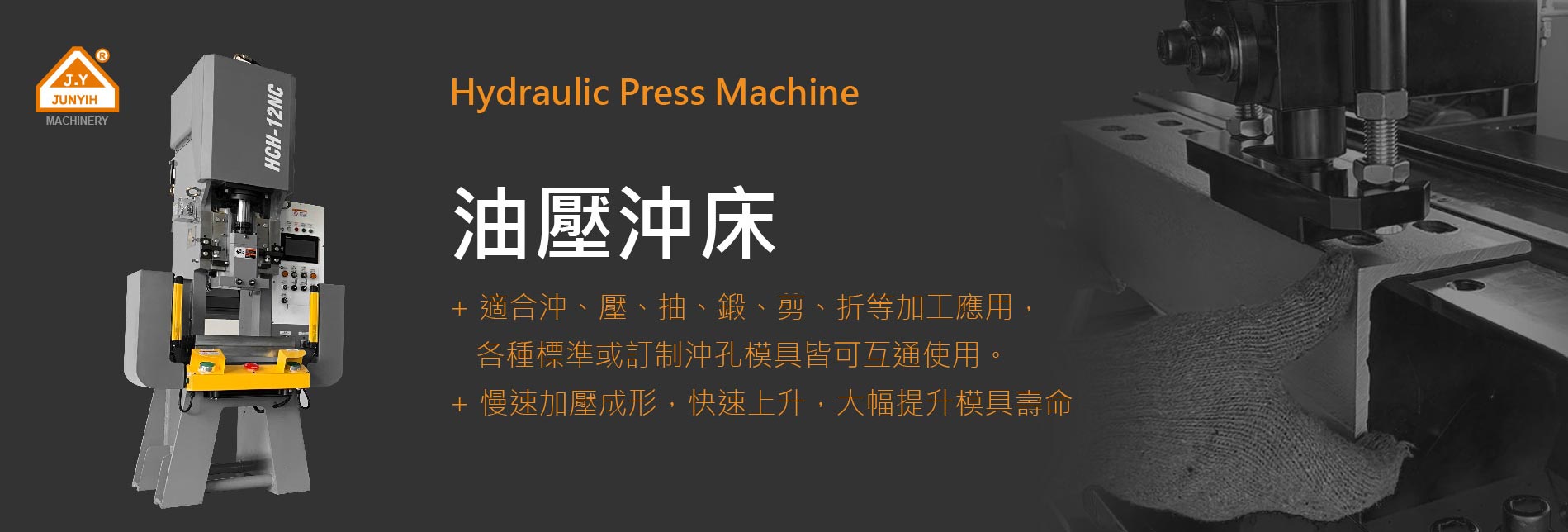

Working Principles and Industrial Applications of Hydraulic Press Machines

What Is a Hydraulic Press Machine?

A hydraulic press machine is a type of equipment that uses hydraulic system pressure to drive the ram, pressing metals or other materials into specific shapes. Compared to traditional mechanical presses, hydraulic press machines offer stable pressure, flexible operation, and high adjustability, making them especially suitable for applications that require high precision, strong force, and complex forming.

Working Principles of Hydraulic Press Machines

The core principle of hydraulic press machines is based on Pascal’s Law: pressure applied to a confined fluid is transmitted uniformly. When the hydraulic pump delivers pressure to the cylinder, the piston generates downward force, which drives the ram and die to apply stable pressure on the workpiece, completing processes such as punching, cutting, or forming.

Main components include:

• Hydraulic Cylinder: The source of pressure.

• Ram/Slider: Applies force directly to the workpiece.

• Worktable: Supports the die and workpiece.

• Hydraulic System: Controls pressure levels and movement speed.

Key Industrial Applications of Hydraulic Press Machines

1. Metal Fabrication Industry

• Suitable for sheet metal punching, forming, and stamping.

• Commonly used in the production of metal parts, hardware tools, aluminum sheets, and steel plates.

2. Automotive Parts Manufacturing

• Applied in body structure parts and chassis components for drawing, bending, and punching.

• Meets requirements for high-strength and mass production.

3. Construction Steel Processing

• Processes rebar, section steel, and angle steel.

• Combined with dies, it can perform cutting, punching, and notching functions.

4. Screw and Fastener Industry

• Widely used in screw and nut manufacturing, requiring precise punching and pressing.

5. Advertising Signage and Metal Products

• Applied to aluminum sheet punching, decorative shaping, and signage fabrication.

How to Select the Right Hydraulic Press Machine

1. Pressure Requirement

• Small parts: choose 10–30 tons hydraulic press.

• Large plates or structural components: require 100 tons or above.

2. Worktable Size

• Select based on workpiece dimensions to ensure sufficient space for the die.

3. Stroke and Speed

• Stroke should be sufficient for deep drawing or thick plate forming.

• Speed must match production line needs for both efficiency and precision.

4. Multi-Function Integration

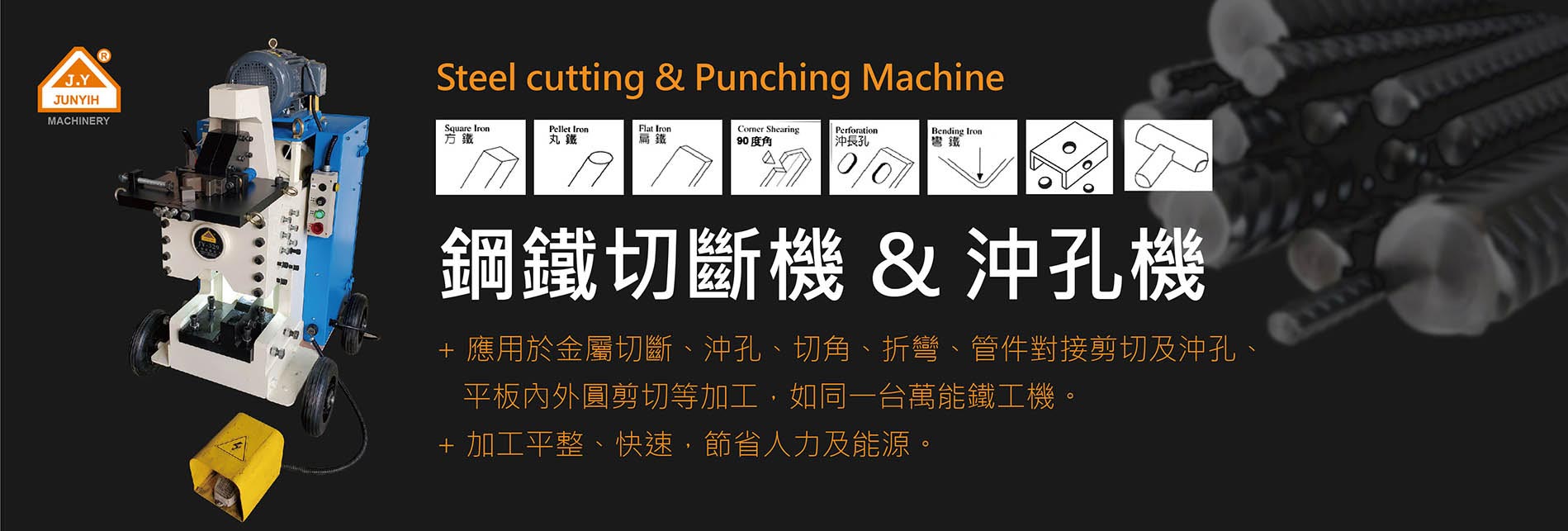

• For combined punching and cutting, consider a Universal Ironworker Machine or a Hydraulic Punching & Cutting Machine.

The hydraulic press machine has become a core piece of equipment in metal fabrication, construction steel processing, and automotive parts manufacturing, thanks to its high precision, strong force, and versatile applications.

When selecting a hydraulic press, factors such as pressure requirements, workpiece size, stroke speed, and multi-function capabilities should be carefully evaluated to maximize production efficiency and ensure processing quality.

Learn more about the Hydraulic Press Machine, its operating principles, and structural details by visiting our Product Introduction Page to explore different models, applications, and performance features.