How to Choose the Right Hydraulic Press? Capacity, Stroke, and Die Matching Tips

Why Choosing the Right Hydraulic Press Matters?

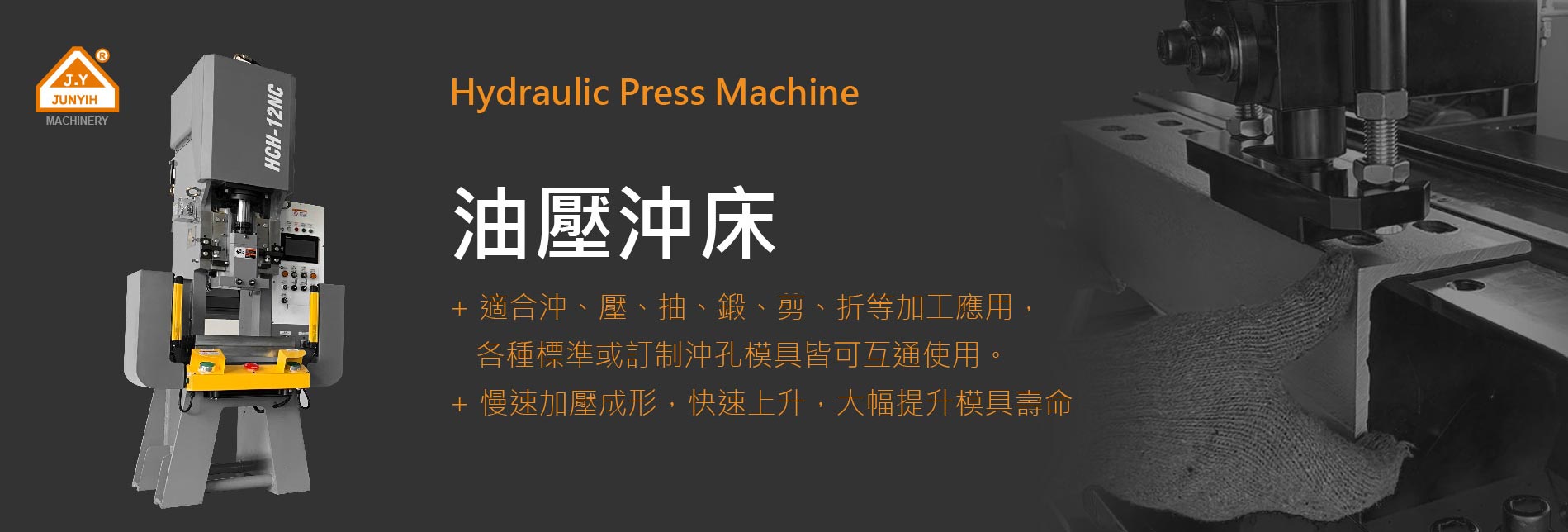

A hydraulic press machine is a crucial piece of equipment in metal fabrication and structural manufacturing. Whether it is punching, cutting, stamping, or forming, each production need requires a press with the right specifications. Choosing the wrong machine can lead to insufficient pressure, reduced die life, lower production efficiency, and even compromised product quality. Understanding how to select a hydraulic press based on capacity, stroke, and die compatibility is essential for both efficiency and quality.

Selecting the Proper Capacity

The capacity (tonnage) of a hydraulic press machine refers to the maximum pressure the equipment can provide, usually measured in tons.

• Small-scale production (10–30 tons)

Suitable for hardware parts, small sheet metal components, and electronic parts.

• Medium-scale production (50–100 tons)

Ideal for automotive parts, aluminum sheets, and steel plates with moderate thickness.

• Large-scale production (100 tons and above)

Used for construction steel, heavy-duty components, and thick metal plates.

When determining capacity, it is important to calculate the required pressure based on the material, thickness, and die shape of the workpiece. A 10–20% safety margin should be reserved to prevent the machine from long-term overload operation.

Stroke and Speed Considerations

The stroke of a hydraulic press determines the distance the ram can travel up and down, directly affecting whether the die can properly process the workpiece.

•Insufficient stroke

May result in incomplete punching or deep drawing, causing defects.

•Excessive stroke

Provides versatility for different parts but may reduce efficiency and increase cycle time.

The stroke should be set according to the die height and the processing depth of the workpiece, while the operating speed should balance production efficiency and forming quality for optimal results.

Die and Press Compatibility

Dies are the core of hydraulic press applications, and different dies require matching machine specifications.

•Die size and worktable area

Ensure the die fits safely on the worktable with sufficient space for installation and removal.

•Die pressure requirement

The press capacity must exceed the die’s required pressure; otherwise, premature die wear may occur.

•Die precision requirement

High-precision dies should be paired with stable hydraulic systems to maintain processing accuracy.

Common Mistakes and How to Avoid Them

1. Focusing only on tonnage without considering stroke → Leads to improper die installation or incomplete processing.

2. Not reserving a safety margin → Continuous full-load operation shortens machine life.

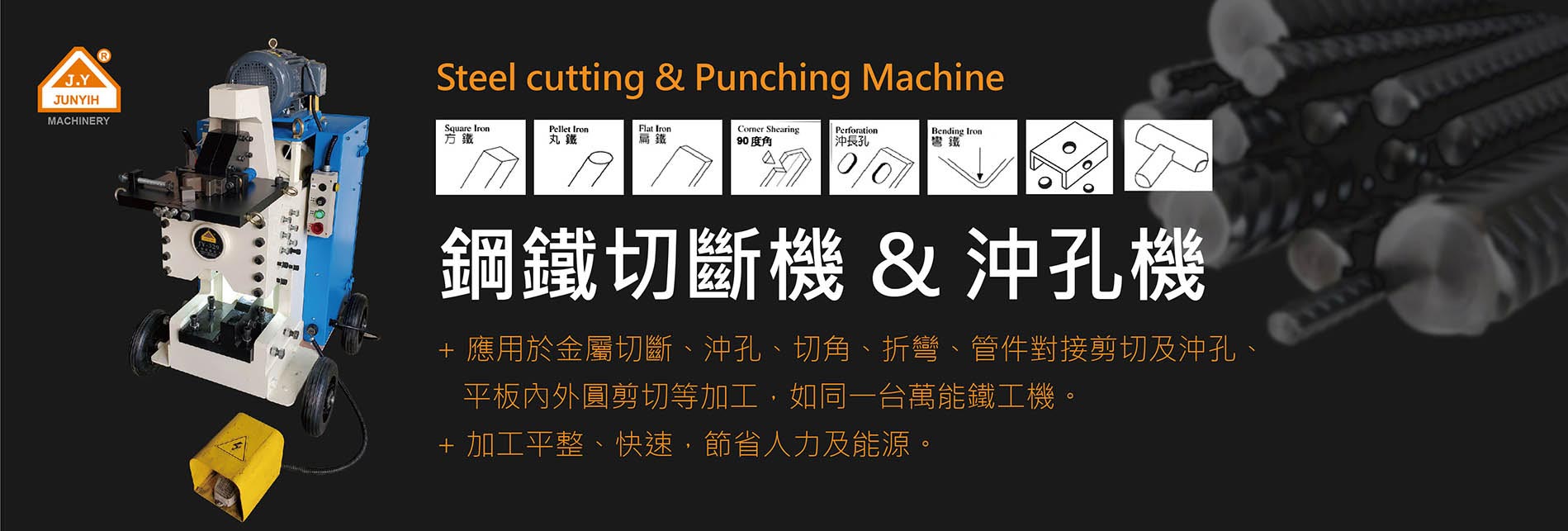

3. Ignoring application scenarios → Rebar cutting in construction differs greatly from precision punching in electronics and requires specialized equipment.

Selecting the right hydraulic press machine requires evaluating capacity, stroke, and die compatibility, not just tonnage.

•Small parts → 10–30 tons

•Medium-sized components → 50–100 tons

•Heavy steel structures → 100 tons and above

With the correct stroke settings and properly matched dies, manufacturers can improve production efficiency, extend machine and die lifespan, and achieve greater overall profitability.

If you are currently evaluating the Hydraulic Press Machine models and capacities, we recommend exploring JUNYIH MACHINERY’s SD Series Hydraulic Press Product Page to understand the differences in tonnage and stroke design.