Differences Between Hydraulic Punching Machines and Traditional Mechanical Punching

Why Compare Hydraulic vs. Mechanical Punching?

In the metal fabrication industry, punching operations are among the most common processes. The two most widely used types of equipment are the Hydraulic Punching Machine and the Mechanical Punching Press. These machines differ significantly in working principles, pressure output, precision, applications, and maintenance costs. Understanding these differences helps manufacturers choose the right solution for their production needs.

Differences in Working Principles

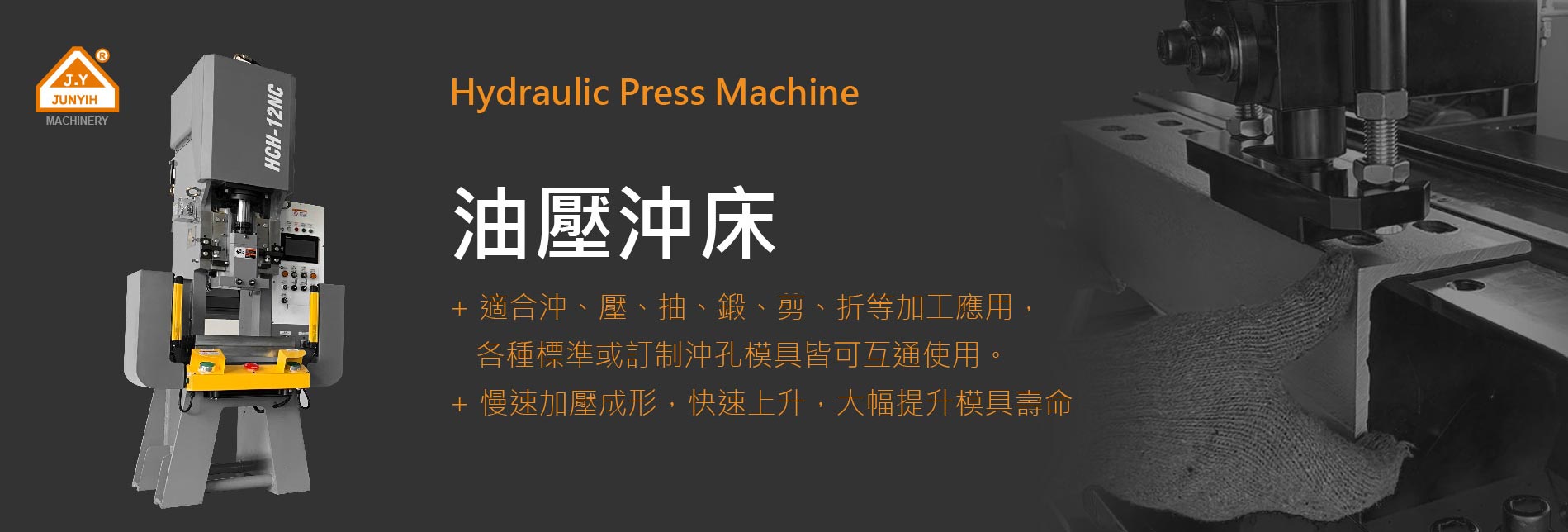

1. Hydraulic Punching Machine

Uses a hydraulic system to generate pressure. The hydraulic cylinder pushes the ram, driving the die to perform the punching operation. Pressure output is stable and can be precisely controlled.

2. Mechanical Punching Press

Uses a crankshaft or eccentric wheel mechanism to convert rotary motion into linear impact force. The punching action is fast, but the pressure output is fixed with less flexibility.

Pressure Output and Processing Precision

1. Hydraulic Punching Machine

• Adjustable pressure, suitable for different thicknesses and materials.

• Provides uniform force during punching, resulting in smooth surfaces and higher accuracy.

2. Mechanical Punching Press

• Relies on mechanical structure for instantaneous high-impact force with fast operation speed.

• Ideal for mass production of standardized parts but less consistent in precision.

Application Scope

1. Hydraulic Punching Machine

• Suitable for sheet metal, aluminum, stainless steel, structural steel, and signage production.

• Best for small to medium batch orders, diversified product requirements, and high-precision applications.

2. Mechanical Punching Press

• Commonly used in hardware parts, electronic components, and screw manufacturing.

• Provides high efficiency in large-scale, repetitive production with the same die setup.

Operation and Maintenance Costs

1. Hydraulic Punching Machine

• Pros: High safety, flexible pressure adjustment.

• Cons: Requires regular maintenance of the hydraulic system, leading to slightly higher costs.

2. Mechanical Punching Press

• Pros: Simple structure, easier to repair.

• Cons: Generates high noise and vibration, causing faster die wear.

• The Hydraulic Punching Machine is better suited for industries requiring precision, flexibility, and adaptability to different materials.

• The Mechanical Punching Press is more suitable for large-scale, high-speed, and standardized mass production.

When selecting equipment, companies should consider product type, production volume, precision requirements, and budget. If stable quality and versatility are the priority, a hydraulic punching machine is the better choice. If speed and mass output are key, a mechanical punching press is more appropriate.

To learn more about the precise structure and control system of the Hydraulic Punching Machine,

please refer to JUNYIH MACHINERY’s Hydraulic Punching Machine SD-60 product page

to explore its high stability and efficiency in metal processing and mold punching applications.