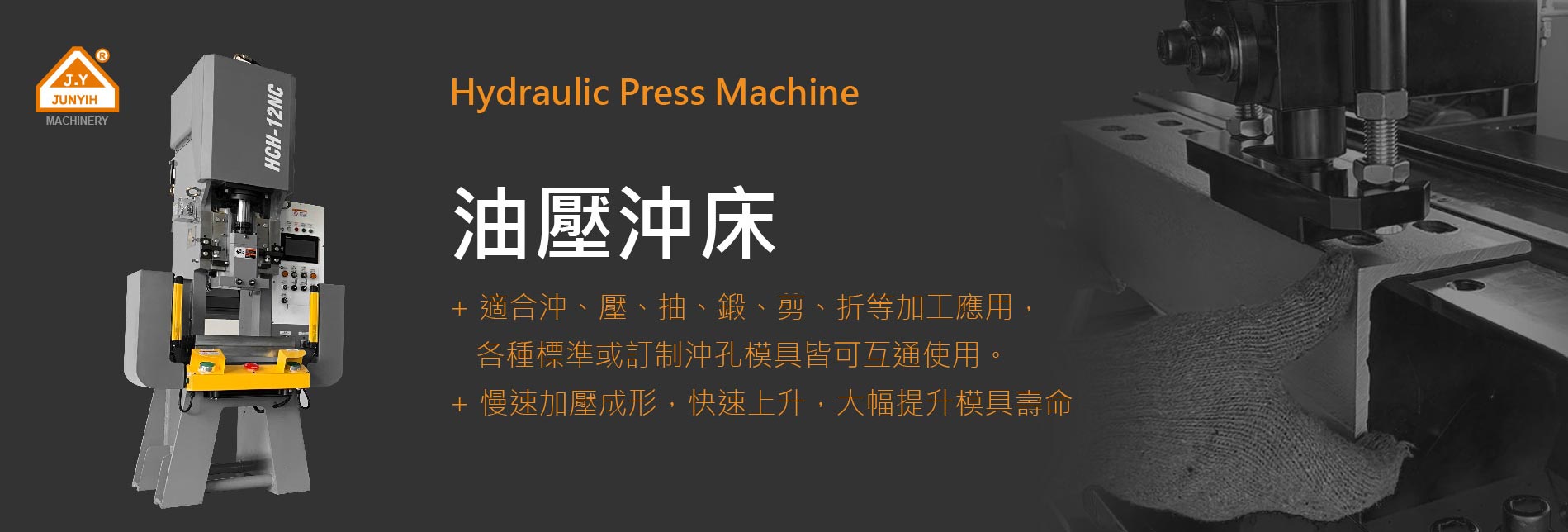

Key Maintenance Tips and Troubleshooting for Hydraulic Punching Machines

Why Regular Maintenance Is Essential for Hydraulic Punching Machines

A Hydraulic Punching Machine is widely used in steel plates, aluminum sheets, stainless steel, and construction steel processing. Since the machine operates under high pressure and frequent cycles, lack of proper maintenance can lead to hydraulic system failures, reduced punching accuracy, and shortened die lifespan. Regular maintenance and timely troubleshooting not only extend equipment life but also ensure stable production efficiency.

Common Maintenance Tips for Hydraulic Punching Machines

1. Hydraulic Oil Inspection and Replacement

• Hydraulic oil is the core of the system and must remain clean with proper viscosity.

• Check oil quality every 6–12 months. Replace immediately if discoloration or contamination is observed.

2. Filter and Strainer Cleaning

•Impurities in hydraulic oil can clog filters and affect pressure stability.

•Regularly clean or replace filters to keep the system running smoothly.

3. Cylinder and Piston Inspection

• Check for oil leakage, wear, or abnormal noise in the hydraulic cylinder.

• Replace worn seals promptly to prevent pressure loss.

4. Die and Worktable Maintenance

• Keep dies clean and properly lubricated to avoid burrs or poor punching quality.

• Regularly calibrate the worktable to ensure accurate die alignment.

5. Electrical and Safety System Testing

• Periodically test control buttons, sensors, and emergency stop devices.

• Ensure operators can stop the machine immediately in case of emergencies.

Common Issues and Troubleshooting Methods

1. Insufficient Punching Pressure

• Possible causes: low hydraulic oil, worn seals, or pump malfunction.

• Solution: check oil level, measure pump pressure, and replace seals if necessary.

2. Slower Punching Speed

• Possible causes: clogged filter, blocked oil circuit, or degraded hydraulic oil.

• Solution: clean filters, check oil passages, and replace hydraulic oil.

3. Abnormal Vibration or Noise

• Possible causes: air in the hydraulic system, pump wear, or loose components.

• Solution: inspect seals and fittings, bleed air from the system, and replace worn parts.

4. Die Misalignment

• Possible causes: improper worktable calibration or incorrect die installation.

• Solution: recalibrate the worktable and check die positioning.

How to Extend the Service Life of a Hydraulic Punching Machine

• Establish a regular maintenance schedule (daily inspection, monthly service, annual overhaul).

• Use OEM-recommended hydraulic oil and components.

• Train operators to ensure proper machine usage.

• Keep detailed maintenance records to assist in troubleshooting future issues.

The stable performance of a Hydraulic Punching Machine depends on proper maintenance and timely troubleshooting.

• Key areas include hydraulic oil, filters, cylinders, dies, and control systems.

• Common issues such as insufficient pressure, slower speed, abnormal vibration, and die misalignment can often be quickly diagnosed with systematic checks.

By implementing good maintenance practices, manufacturers can extend machine lifespan, ensure production stability, and maintain product quality.