Gantry-Type Hydraulic Drawing & Forming Press

Gantry-Type Hydraulic Drawing & Forming Press

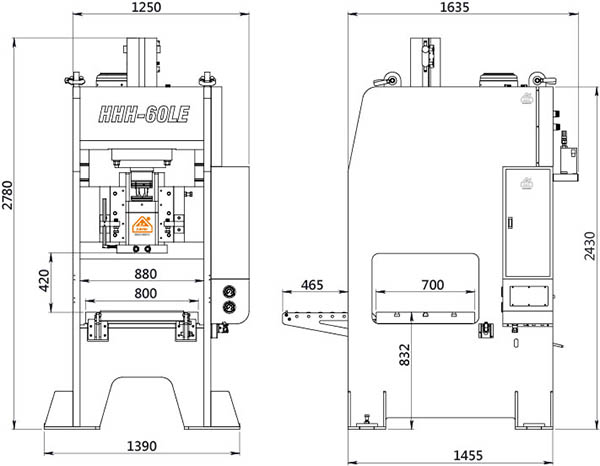

Model: HHH-LE

Maximum Hydraulic Press Capacity: 60 tons (specifications and tonnage can be customized).

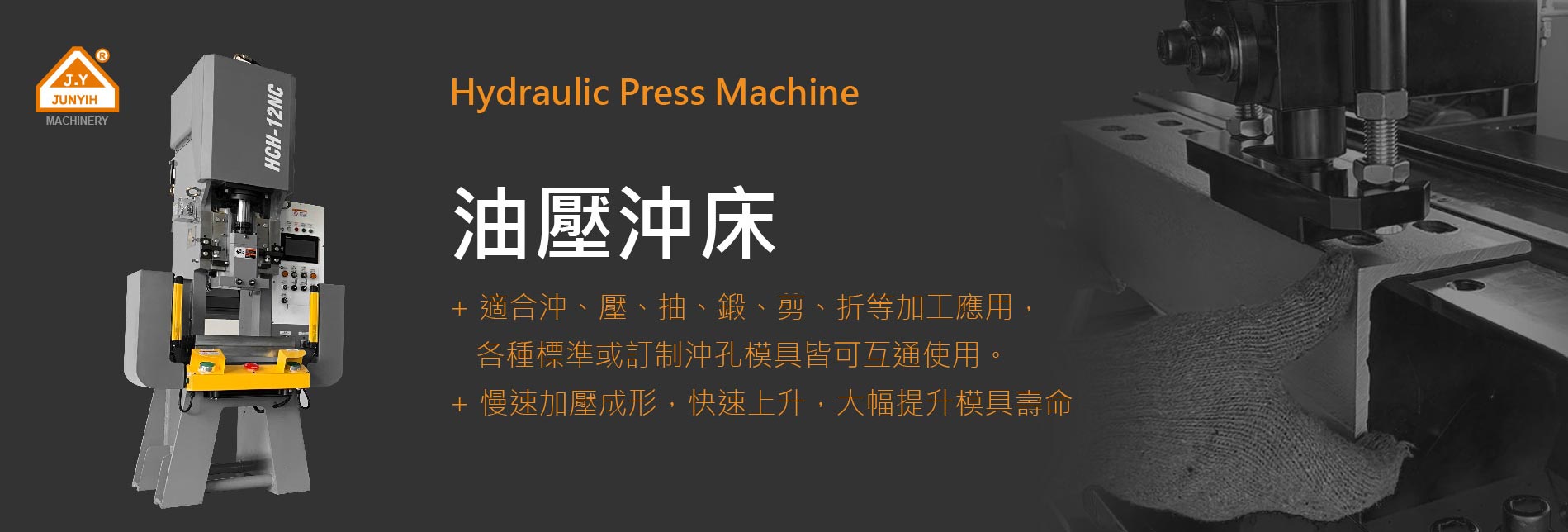

The H-Frame Deep Drawing Hydraulic Press is designed with a one-piece high-rigidity H-frame structure, ideal for deep drawing, metal forming, and large sheet processing.

Equipped with a smart HMI touchscreen, it allows precise setup of stroke, pressure, and dwell time for improved efficiency.

The H-Frame Hydraulic Press supports automatic feeding, robotic handling, positioning gauge, and quick die change systems, widely used in automotive parts, sheet metal forming, mechanical enclosures, and electrical panels.

Precision:

-

The Gantry-Type Hydraulic Drawing & Forming Press is specially designed for deep drawing applications, featuring a high-strength one-piece side-wall frame that ensures durability, stability, and precision during stamping operations.

-

Patented threaded fine-adjustment mechanism on the slider allows micro-adjustment at the lower stroke limit, improving the accuracy of formed workpieces.

-

Unique convex guide design enables easy clearance adjustment, providing high rigidity, impact resistance, and low wear.

Performance:

-

Equipped with a touchscreen HMI interface for simple operation settings and fast die setup.

-

Compatible with automation systems, including robotic infeed/outfeed devices, roller-type die transfer arms, and automatic die clamps.

-

Hydraulic power system ensures energy-saving and low-noise operation, with no mechanical flywheel inertia loss during the stroke. Suitable for punching, pressing, drawing, forging, shearing, and bending applications.

-

Die clamping system is compatible with conventional mechanical presses, allowing interchangeability of both new and existing dies.

-

Air-cooled forced cooling system supports reliable long-term continuous operation.

Safety:

-

Designed in compliance with labor safety inspection standards.

-

PLC automatic control offers inching, single-stroke, automatic feeding, and multi-machine linkage functions.

-

Piano-style control panel allows operation via single-hand, double-hand, or foot pedal modes.

-

Equipped with a safety light curtain to prevent accidental injury.

.jpg)

The press machine is equipped with multiple advanced features to enhance precision, efficiency, and operator safety.

1. Patented rear-exit hydraulic cylinder slide rod structure – ensures precise stopping position of the slider during downward motion.

2. Touchscreen control panel – allows parameter settings, provides abnormal alarm notifications, and records operation history.

3. Roller-type die transfer arm (optional) – enables smoother die handling and positioning.

4. Quick die change device (die clamp, optional) – saves time and effort when replacing dies.

5. Movable piano-style control panel – offers three operation modes: single-hand, double-hand, or foot pedal.

6. Additional safety light curtain – prevents accidental operator injury.