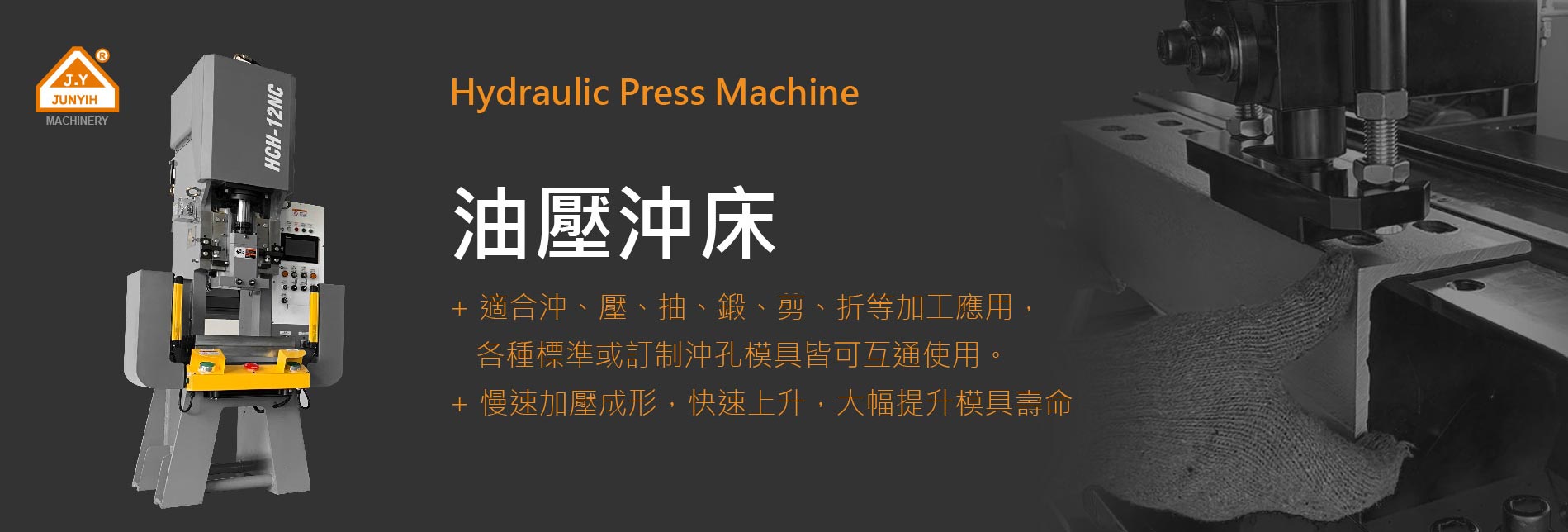

NC C-Frame CNC Hydraulic Press

NC C-Frame CNC Hydraulic Press

Model: HCH-NC

Capacity: 12–60 tons

The NC C-Frame CNC Hydraulic Press features a touchscreen NC control system, enabling storage of multiple die positions and processing parameters. Ideal for precision punching, forming, bending, and cutting operations.

With its PLC + NC dual control structure, it achieves high-accuracy stroke control and adjustable high/low pressure speeds, increasing productivity and extending die life.

The NC Series Hydraulic Press supports automatic feeding, quick die change, and multi-machine linkage, making it perfect for mass metal production, hardware stamping, and automated press lines.

Precision:

- Touchscreen control for precise adjustment of slider upper and lower limits.

- Convex guide design allows easy clearance adjustment, offering high rigidity, impact resistance, and low wear.

- Machine frame adopts a high-rigidity steel plate welding and integrated machining structure for maximum stability.

Performance:

-

Hydraulic power system delivers energy-saving, low-noise operation with no kinetic energy loss during stroke. Suitable for punching, pressing, drawing, forging, shearing, and bending applications.

-

Die clamping system is compatible with conventional mechanical press machines, allowing interchangeability of both new and existing dies.

-

NC program control can store multiple die settings for upper/lower limits and variable-speed stroke control.

-

Designed as an optimal application for industrial big data integration.

-

Air-cooled forced cooling system enables continuous long-term operation.

Safety:

-

Machine design complies with labor safety inspection regulations.

-

PLC automatic control provides inching, single-stroke, automatic feeding, and multi-machine linkage modes.

-

Piano-type control panel allows three operation options: single-hand, double-hand, or foot pedal.

-

Equipped with safety light curtain to prevent accidental injury.

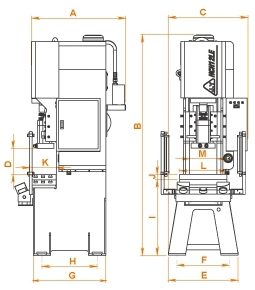

|

Exterior Size |

HCH-12NC |

HCH-18NC |

HCH-25NC |

HCH-40NC |

HCH-60NC |

| A | 900 | 1049 | 1078 | 1166 | 1354 |

| B | 2100 | 2152 | 2332 | 2520 | 2770 |

| C | 751 | 773 | 857 | 960 | 1181 |

| D | 250 | 280 | 290 | 300 | 350 |

| E | 665 | 684 | 812 | 906 | 1086 |

| F | 500 | 585 | 610 | 695 | 846 |

| G | 690 | 850 | 990 | 1090 | 1277 |

| H | 525 | 650 | 790 | 870 | 1010 |

| I | 720 | 715 | 740 | 730 | 750 |

| J | 50 | 55 | 60 | 70 | 80 |

| K | 250 | 273 | 323 | 360 | 430 |

| L | 450 | 500 | 600 | 700 | 800 |

| M | 258 | 274 | 316 | 356 | 446 |

| Unit:mm | |||||

|

Item / Model |

Unit |

HCH-12NC |

HCH-18NC |

HCH-25NC |

HCH-40NC |

HCH-60NC |

| Stamping Capacity | tons | 12 | 18 | 25 | 40 | 60 |

| Stroke | mm | 60 | 70 | 80 | 90 | 100 |

| Closing Height | mm | 190 | 210 | 210 | 210 | 250 |

| Max. Mold Height | mm | 250 | 280 | 290 | 300 | 350 |

| Slider Adjustment | mm | 110 | 120 | 120 | 130 | 130 |

| Slide Area | mm | 191x359 | 207x393 | 231x424 | 254x470 | 320x515 |

| Die Hole | mm | Ø38.1 | Ø38.1 | Ø38.1 | Ø50.8 | Ø50.8 |

| Table Size | mm | 250x450 | 270x500 | 320x600 | 360x700 | 430x800 |

| Table Aperture | mm | Ø130 | Ø150 | Ø165 | Ø180 | Ø200 |

| Table Thickness | mm | 50 | 55 | 60 | 70 | 80 |

| Main Motor | HP | 2HP / 4P | 3HP / 4P | 5HP / 4P | 7.5HP / 4P | 10HP / 4P |

■ Specifications and table dimensions can be fully customized. In addition, we welcome inquiries for die manufacturing, quick die change systems, feeding equipment, and complete automation solutions.

HCH-NC

<<BACK