Three Effective Techniques to Improve Vertical Steel Cutting Efficiency

In the fields of metal fabrication and construction steel processing, the Vertical Type Steel Cutting Machine is widely used due to its compact footprint and stable cutting performance. For many factories, the challenge lies in improving efficiency without compromising cutting quality. This article shares three practical tips to help businesses boost productivity, reduce costs, and extend equipment lifespan.

Tip 1: Choose the Right Cutting Blades and Match Materials

• One of the most critical factors affecting efficiency is blade selection.

• For rebar and round bar applications (Round Bar Steel Cutting Machine), high-hardness alloy blades should be used to minimize resistance and burr formation.

• Regularly inspect blade wear and sharpen or replace them in time to avoid overloading the machine due to poor cutting performance.

Tip 2: Set Proper Hydraulic Pressure and Cutting Parameters

• Although the vertical design provides stable force, insufficient pressure or overly fast stroke speed can lead to rough or inaccurate cuts.

• It is recommended to adjust the tonnage based on material thickness and diameter, leaving a 10–20% safety margin to prevent long-term overload.

• Cutting speed should balance productivity and blade lifespan rather than maximizing speed alone.

Tip 3: Strengthen Lubrication and Cooling Systems

• Continuous processing generates heat from blade-workpiece friction, accelerating tool wear.

• Equip the Vertical Type Steel Cutting Machine with an automatic lubrication or cooling system to reduce friction, stabilize cutting, and improve surface quality.

• This not only extends blade life but also ensures consistent accuracy.

Extended Applications: Multi-Functional Solutions

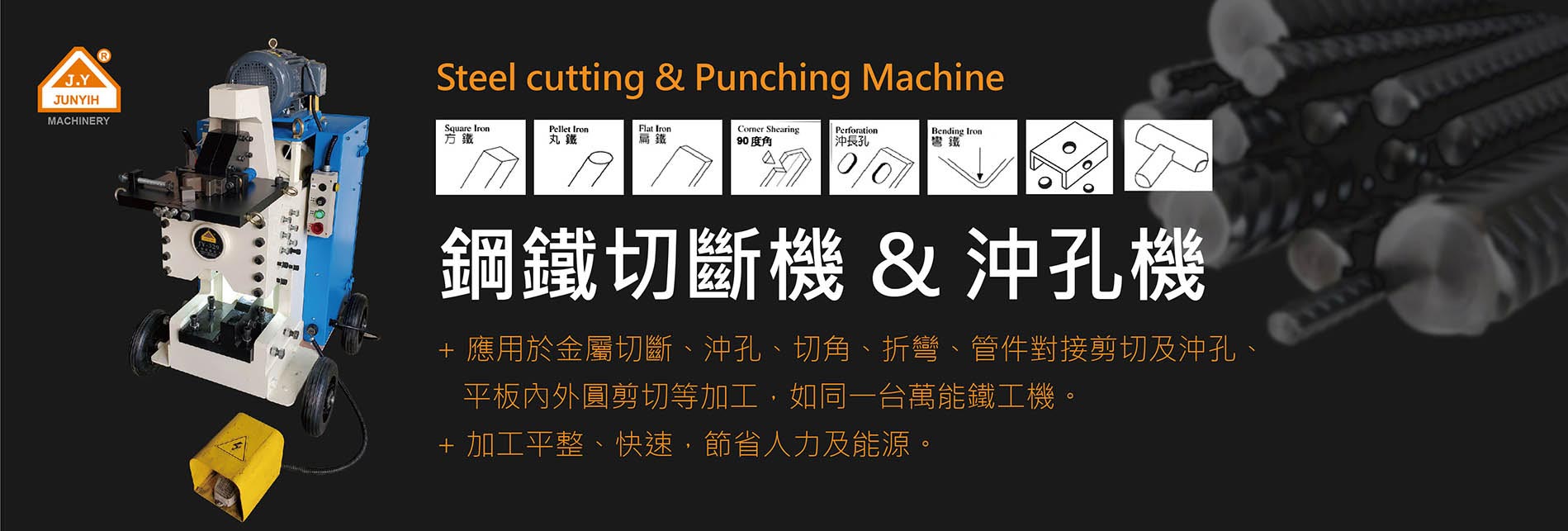

Beyond specialized vertical steel cutting machines, many workshops adopt Ironworker Machines or Universal Ironworker Machines, which combine cutting, punching, and notching functions. These versatile solutions are particularly useful for small to medium-sized factories seeking multi-tasking capabilities.

To maximize the efficiency of the Vertical Type Steel Cutting Machine, businesses should focus on:

1. Selecting the right blades and matching them to the material.

2. Setting proper hydraulic pressure and stroke parameters.

3. Enhancing lubrication and cooling systems.

By applying these three techniques, manufacturers can significantly improve production efficiency while maintaining cutting precision and machine stability—ensuring stronger competitiveness in the metal fabrication and construction steel industries