Essential Guide to Rebar Cutting Machines: Selection and Safe Operation on Construction Sites

In modern construction sites, rebar cutting is one of the most frequent and critical tasks. A Rebar Cutting Machine has become an indispensable tool due to its efficiency, safety, and reliability. This article explains the key features, selection tips, and safe operation guidelines for rebar cutting machines, helping construction teams improve productivity while ensuring workplace safety.

Functions and Features of Rebar Cutting Machines

Rebar cutting machines are designed to cut different types of rebar, round bars, and construction steel rods. Their key features include:

• High Efficiency: Quickly cuts through various diameters and materials, reducing work time.

• Durability and Stability: Equipped with hardened blades and rigid frames to ensure long-term precision and consistent performance.

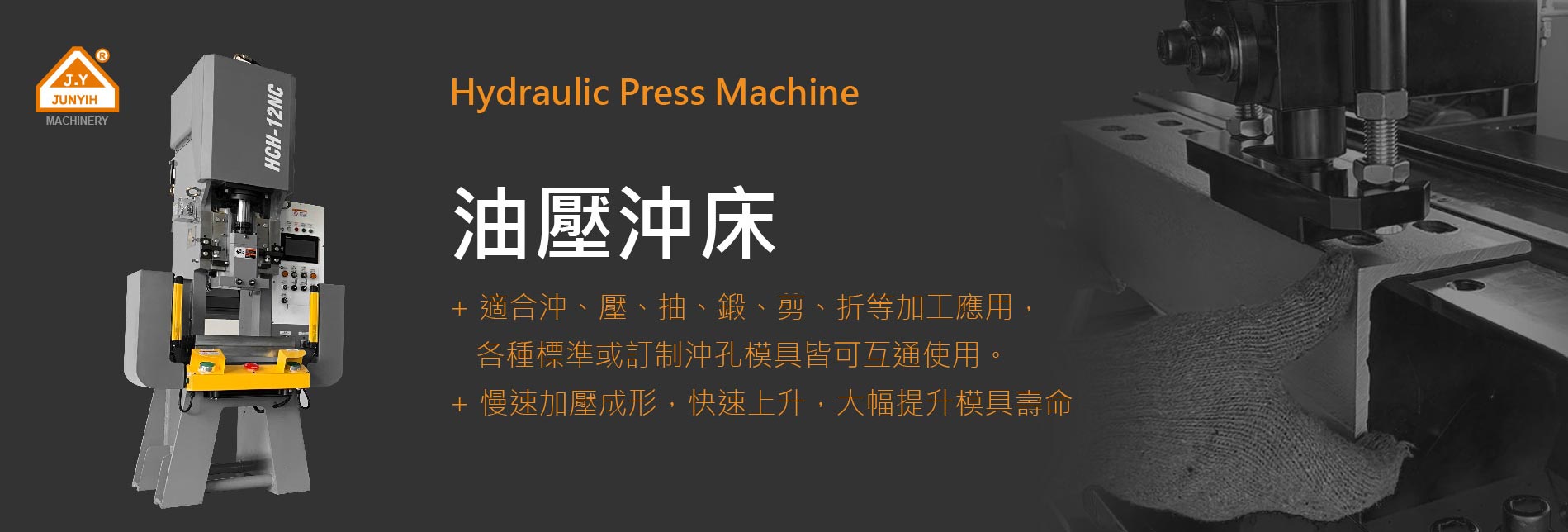

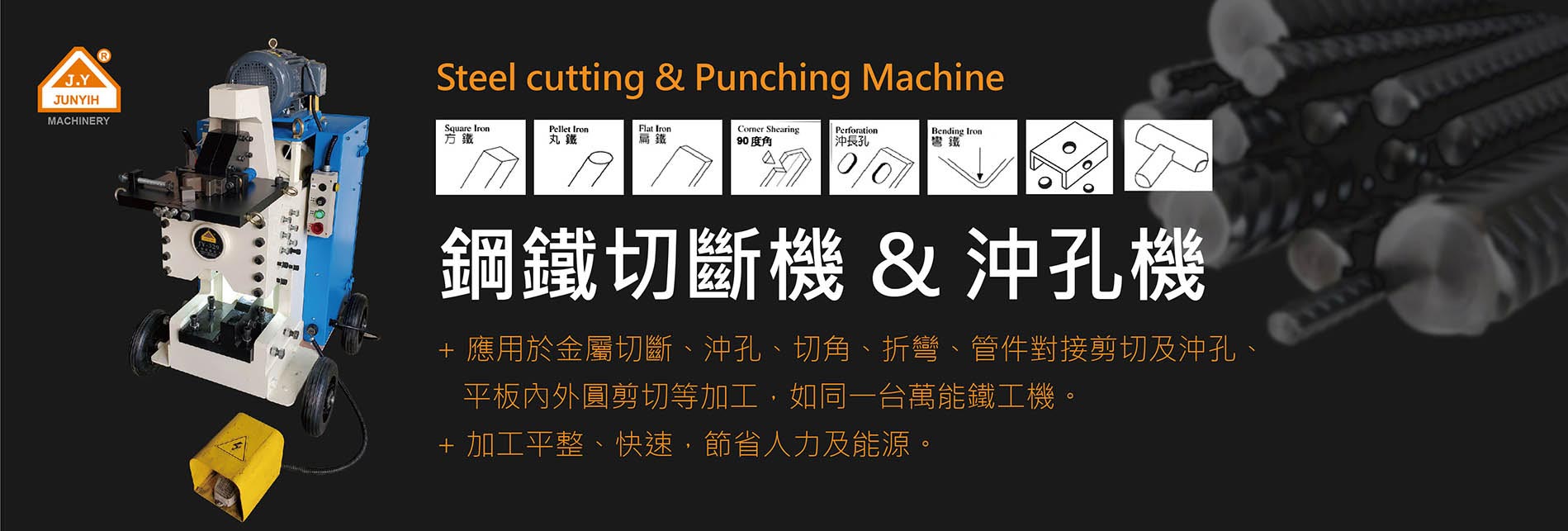

• Versatile Designs: Available in models such as Steel Cutting Machine (Vertical Series), horizontal rebar cutters, and multifunctional Ironworker Machines that combine cutting and punching.

These features make them highly suitable for construction projects, steel fabrication, and infrastructure applications.

Key Factors for Choosing the Right Machine

Selecting the correct machine depends on your project’s requirements:

• Cutting Capacity: Verify the maximum rebar diameter the machine can handle, and always leave a 10–20% safety margin to avoid long-term overloading.

• Machine Type: Vertical designs are ideal for stable, continuous operations, while horizontal machines work better in tight spaces or for mobile applications.

• Application Needs: For facilities that also require punching, consider multifunctional solutions such as a Steel Cutting Machine / Round Bar Steel Cutting Machine combined with punching functions to enhance flexibility.

Safe Operation Guidelines

Since rebar cutting involves high pressure and sharp blades, proper safety practices are essential:

• Inspect blades and bolts before each operation to ensure machine readiness.

• Keep rebar aligned and stable during cutting to avoid blade damage or material rebound.

• Operators must wear safety glasses, gloves, and protective footwear, and restrict access to unauthorized personnel.

• Perform routine maintenance such as checking hydraulic oil, lubrication, and spare parts to prevent malfunctions.

Applications of Rebar Cutting Machines

Rebar cutting machines are widely used in:

• Construction Sites: Reinforcement fabrication and structural steel processing.

• Bridge and Foundation Projects: Large-scale rebar cutting requirements.

• Metal Fabrication Plants: Cutting round bars, steel rods, and structural steel.

• Recycling Industry: Scrap metal cutting and processing.

Their versatility ensures efficiency and safety across different industries.

A Rebar Cutting Machine is essential for construction and steel processing projects. Whether it is a Steel Cutting Machine (Vertical Series) or a multifunctional Ironworker Machine, these machines deliver reliable and efficient cutting solutions. By following the right selection criteria and safe operation practices, construction teams can significantly improve efficiency and workplace safety.

JUNYIH MACHINERY specializes in manufacturing rebar cutting machines, steel cutting machines, and universal ironworker equipment, providing durable and high-performance solutions for construction and metalworking industries worldwide.

To learn more about the specifications and safety design of the Rebar Cutting Machine, please visit JUNYIH MACHINERY’s JY-450 Rebar Cutting Machine product page to see how it meets the high-efficiency construction needs of building sites.