Structural Differences Between C-Frame Presses and H-Frame Presses

In the metalworking and stamping industry, press machines come in different structural designs. Among them, the C-Frame Press (also known as C-Type Press Machine) and the H-Frame Press are two of the most common. Each type has its own strengths in terms of design, force distribution, and application fields. Understanding their differences helps manufacturers make the right equipment choices.

Features of C-Frame Press

• Design: Built in a “C” shape, providing an open structure that allows easy placement and removal of workpieces.

• Force Distribution: Generally uses single-point or double-point loading, simpler in structure but less rigid compared to H-frame designs.

• Advantages:

• Ideal for small to medium-sized stamping tasks.

• Commonly used for punching, bending, forming, and light cutting.

• Open frame makes die changes and workpiece handling more convenient.

Features of H-Frame Press

• Design: Built in an “H” or portal frame structure with two supporting sides, offering higher rigidity.

• Force Distribution: Provides balanced force distribution, capable of handling larger tonnage for heavy-duty applications.

• Advantages:

• Suitable for large workpieces and thick plate processing.

• Widely applied in automotive parts, structural steel, and heavy metal forming.

• High rigidity ensures stability during continuous operations.

Key Differences

1. Rigidity: H-Frame Press offers higher rigidity for heavy loads, while C-Frame Press provides flexibility with less rigidity.

2. Working Space: C-Frame Press provides an open workspace, easier for workpiece placement; H-Frame Press is more enclosed but ensures stable force balance.

3. Applications: C-Frame is common in electronics, hardware, and precision metalworking; H-Frame is preferred in automotive, thick plate stamping, and heavy structures.

The C-Frame Press (C-Type Press Machine) stands out for its flexibility, easy die changes, and suitability for small to medium parts. The H-Frame Press, on the other hand, offers high rigidity and large tonnage capacity, making it ideal for heavy-duty metal processing.

When selecting a press machine, manufacturers should consider part size, material type, and production requirements to choose the most suitable solution.

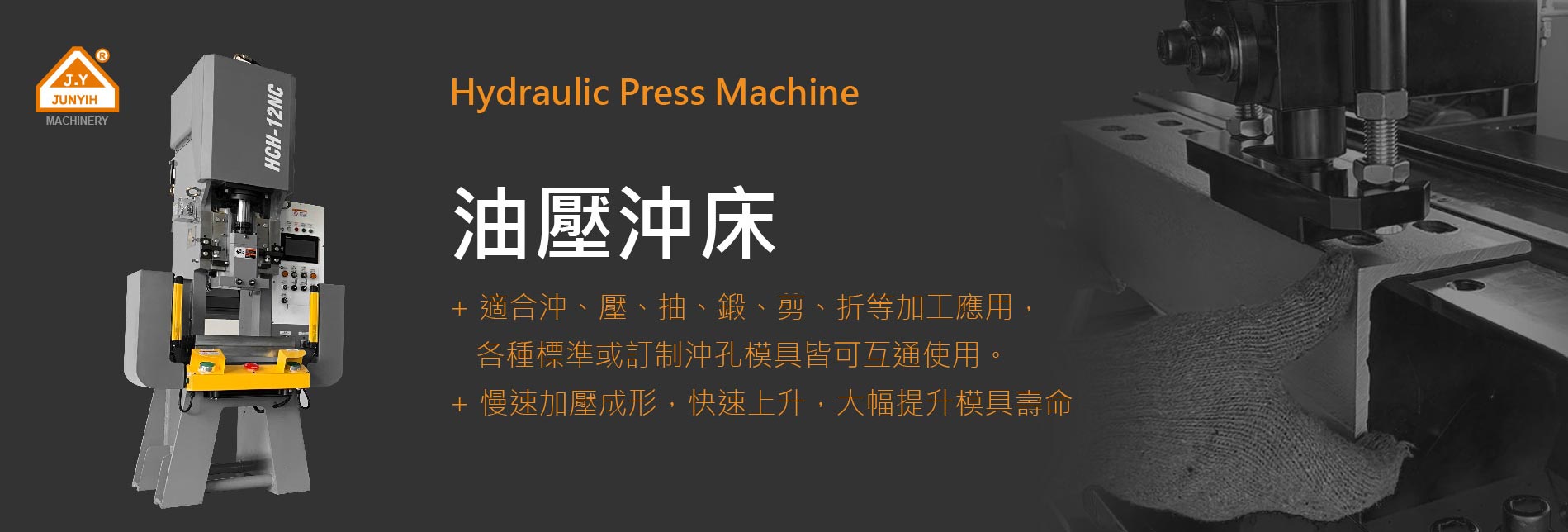

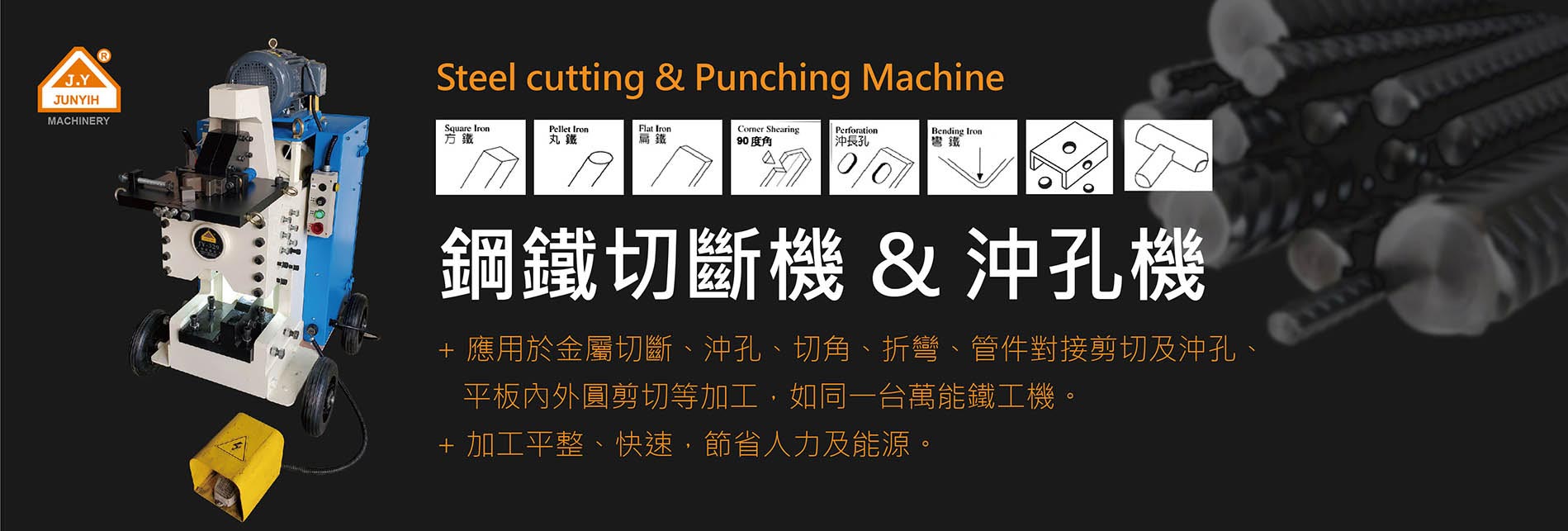

JUNYIH MACHINERY provides a wide range of C-Frame Press, H-Frame Press, and hydraulic press machines, helping customers build efficient and precise production lines.