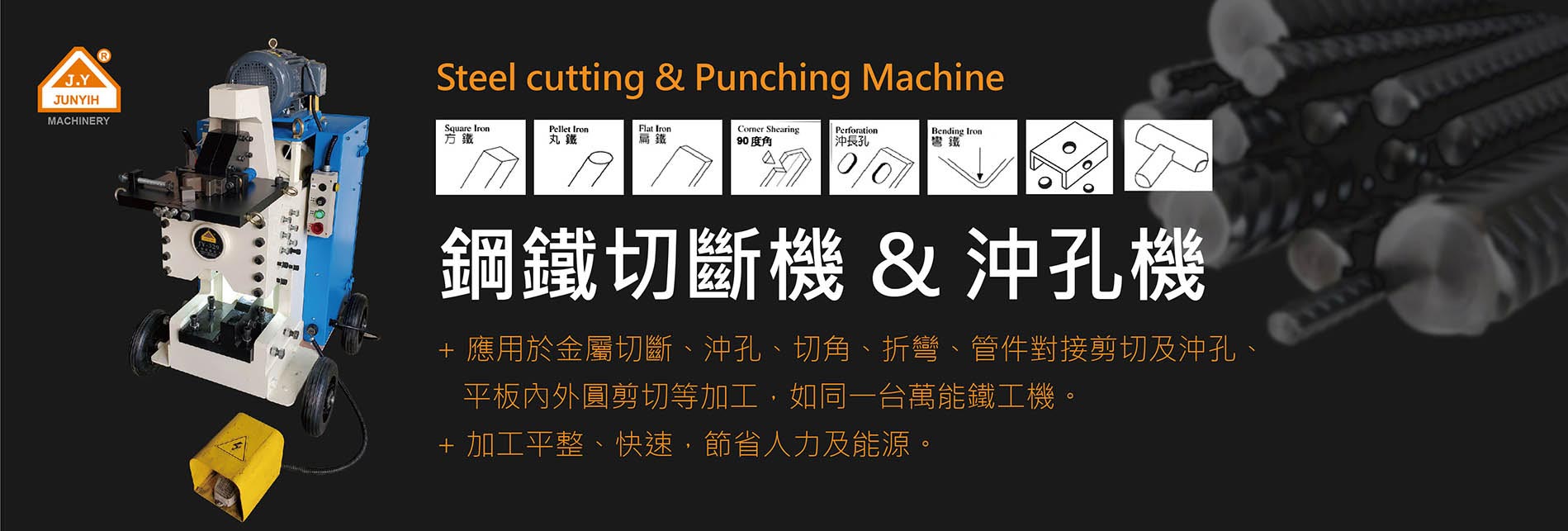

Advantages and Applications of Combined Steel Cutting & Punching Machines

What is a Steel Cutting & Punching Machine?

A Steel Cutting & Punching Machine is an integrated hydraulic system that combines both cutting and punching functions into a single unit. Traditionally, these processes required two separate machines, but with an all-in-one design, manufacturers can perform steel cutting, punching, and slotting operations more efficiently, reducing production time and costs.

Key Advantages of Steel Cutting & Punching Machines

1. Multi-Function, Cost-Saving

• One machine performs both cutting and punching.

• Reduces floor space and the need for multiple operators, lowering overall investment.

2. Improved Production Efficiency

• Eliminates material transfer between different machines.

• Shortens production cycles, ideal for high-volume manufacturing.

3. High Precision Processing

• Hydraulic systems provide stable pressure, ensuring accurate cutting edges and punching positions.

• Minimizes deviations caused by separate operations.

4. Lower Maintenance and Energy Consumption

• Integrated design simplifies maintenance schedules.

• Hydraulic systems are durable and easy to maintain, extending equipment lifespan.

Common Applications of Steel Cutting & Punching Machines

1. Construction Steel Processing

• Widely used for rebar, angle steel, and section steel cutting and punching.

• Suitable for large-scale construction component production.

2. Metal Fabrication Industry

• Processes steel plates, aluminum parts, and stainless steel components.

• Applied in hardware, tools, and general metal manufacturing.

3. Signboard and Advertising Industry

• Used for aluminum signage, steel frames, and punched lettering.

• Flexible for small-batch, customized orders.

4. Recycling and Remanufacturing

• Effective for cutting scrap steel and reprocessing materials, enhancing resource utilization.

How to Select the Right Machine?

• Capacity: Choose based on material thickness and size, with a 10–20% safety margin to avoid overload.

• Workpiece Variety: For different specifications, consider adjustable stroke models.

• Production Mode: Automated models are recommended for high-volume operations.

• Maintenance Support: Ensure reliable after-sales service and parts availability for long-term stability.

The Steel Cutting & Punching Machine offers multi-functionality, efficiency, and precision, making it a vital solution in construction steel processing, metal fabrication, and signboard manufacturing.

When selecting a machine, businesses should evaluate material requirements, production volume, and customization needs to maximize productivity and maintain consistent product quality.

To learn more about the applications and performance of the Steel Cutting & Punching Machine, please visit JUNYIH MACHINERY’s Steel Cutting & Punching Machine JY-329E product page to explore how this multifunctional hydraulic equipment integrates cutting, punching, and bending operations to enhance production efficiency.