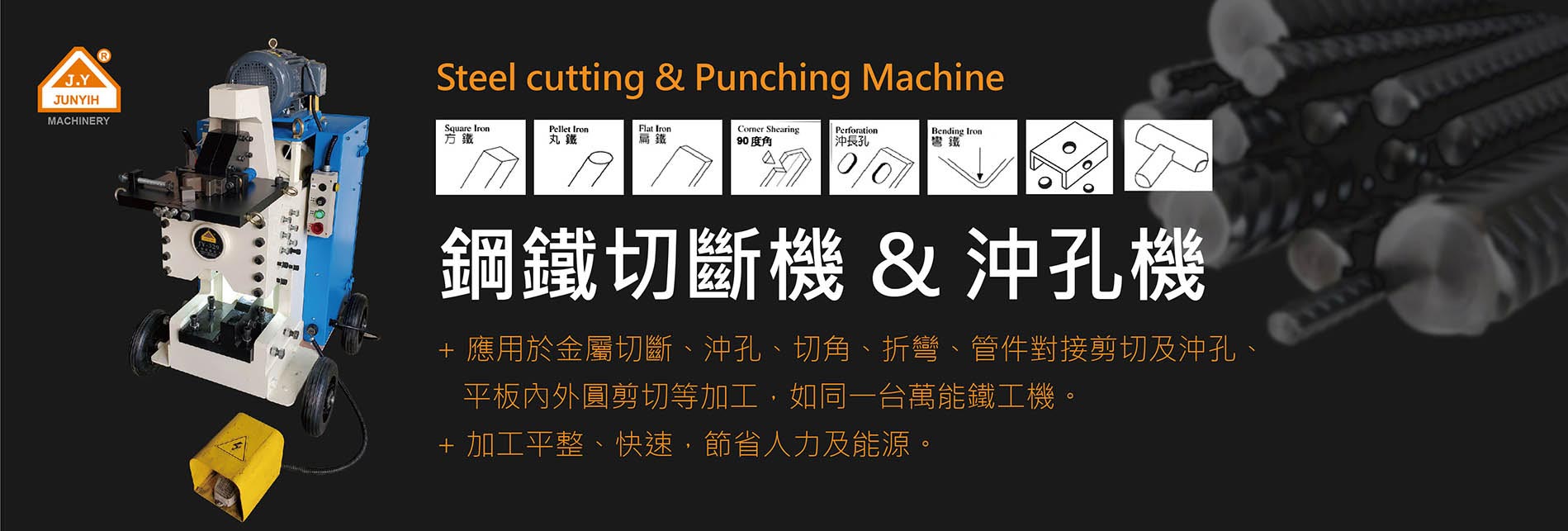

Common Issues in Metal Cutting and Punching Processes and Their Solutions

In the metal fabrication industry, cutting and punching are among the most fundamental and widely used processes. However, as material types diversify and precision requirements increase, manufacturers often face challenges such as excessive burrs, hole misalignment, and short tool life. This article highlights common issues in cutting and punching operations and provides practical solutions to help improve efficiency and product quality.

Problem 1: Excessive Burrs After Cutting

◎ Causes

• Worn-out or unsuitable cutting tools.

• Insufficient pressure from the hydraulic cutting machine, leading to rough edges.

• Material thickness or hardness exceeding machine capacity.

◎ Solutions

• Regularly replace or sharpen cutting tools; use high-hardness alloy materials.

• Adjust hydraulic pressure to ensure stable cutting performance.

• Select the proper tonnage hydraulic cutting machine based on material thickness.

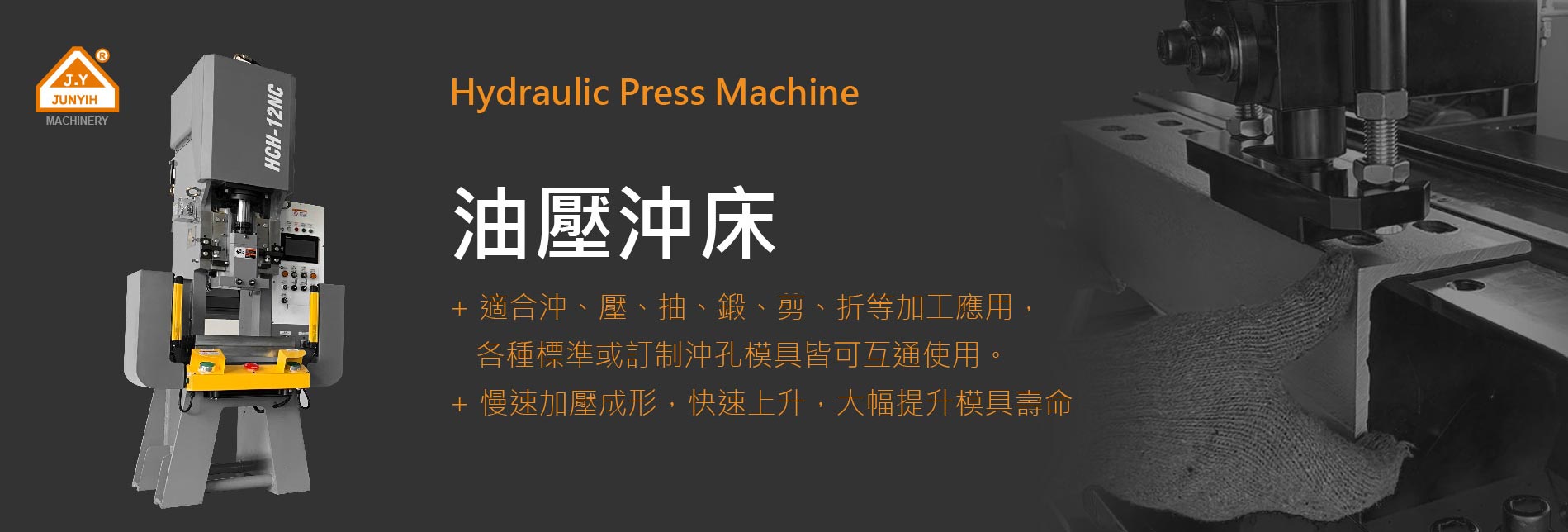

Problem 2: Misaligned Punching Holes

◎ Causes

• Improper mold installation or inaccurate positioning.

• Unstable slide stroke of the hydraulic punching machine.

• Poor workpiece clamping, causing movement during processing.

◎ Solutions

• Ensure precise mold installation and inspect positioning systems regularly.

• Use a stable hydraulic punching machine and avoid long-term overloading.

• Add anti-slip clamping devices to secure the workpiece during punching.

Problem 3: Short Tool/Mold Life

◎ Causes

• Excessive processing speed increases tool wear.

• Lack of lubrication or cooling, resulting in high-temperature damage.

• Impurities or hard spots in materials scratching the mold.

◎ Solutions

• Set reasonable punching and cutting speeds to avoid overloading.

• Apply molybdenum disulfide (MoS₂) grease for lubrication and cooling.

• Use high-precision, wear-resistant molds to extend service life.

Problem 4: High Energy Consumption

◎ Causes

• Long idle running times.

• Inefficient hydraulic systems with severe pressure loss.

• Using oversized or unsuitable machines.

◎ Solutions

• Minimize idle operation and optimize batch scheduling.

• Regularly inspect hydraulic seals and oil conditions.

• Choose the appropriate tonnage hydraulic press or punching machine to match production needs.

While cutting and punching are essential processes in metal fabrication, overlooking key details can lead to reduced product quality, higher mold wear, and increased production costs.

By adopting proper machine selection, regular maintenance, and optimized processing parameters, businesses can ensure that their hydraulic press machines, hydraulic punching machines, and cutting machines operate at maximum efficiency—improving both productivity and competitiveness.