Why Steel Notching Machines Are Essential in Structural Steel Fabrication

The Role of Steel Notching Machines

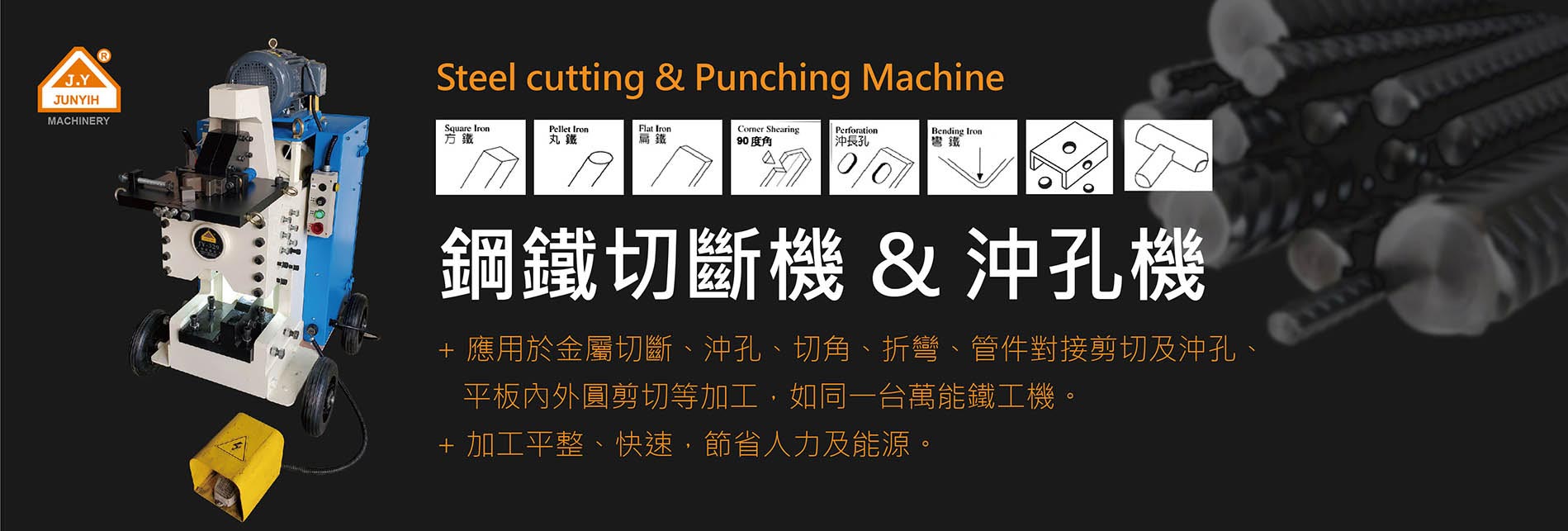

In structural steel fabrication, the Steel Notching Machine plays a critical role. Its main function is to precisely notch section steel, angle steel, and channel steel, ensuring accurate connections for stable construction and consistent appearance.

Without professional notching equipment, issues such as large assembly gaps, uneven load distribution, reduced efficiency, and even safety risks may occur during construction.

Why Structural Steel Requires Steel Notching Machines

1. Accuracy and Safety in Structures

• Steel Notching Machines deliver precise angle control, avoiding errors caused by manual cutting.

• Accurate notching ensures even load distribution in welded or bolted joints, enhancing overall safety.

2. Improved Efficiency

• Manual or non-specialized cutting methods are time-consuming and often require rework.

• Professional notching equipment significantly shortens processing time, ideal for large-scale projects.

3. Reduced Material Waste

• Precision cuts minimize secondary adjustments and material loss.

• Long-term use helps companies save on raw material costs.

4. Adaptability for Diverse Applications

• Structural steel projects often require different angles and specifications.

• Steel Notching Machines, with adjustable stroke and mold designs, meet a wide range of processing needs.

Application Examples

• High-rise buildings: Precise connections between beams and columns.

• Bridge construction: Secure steel connections for extended durability.

• Industrial plants: Large-scale steel frameworks requiring fast assembly.

• Signboard structures: Processing aluminum frames and angle steel supports.

Additionally, multi-functional equipment such as Ironworker Machines and Universal Ironworker Machines often integrate notching functions along with cutting and punching, making them popular for small to medium-sized fabrication shops.

In structural steel fabrication, the Steel Notching Machine ensures accuracy, safety, efficiency, and cost savings, making it a key piece of equipment for quality and timely construction.

For both large-scale projects and small to medium-sized workshops, investing in a reliable notching machine or multi-functional Ironworker Machine enhances productivity and strengthens market competitiveness.